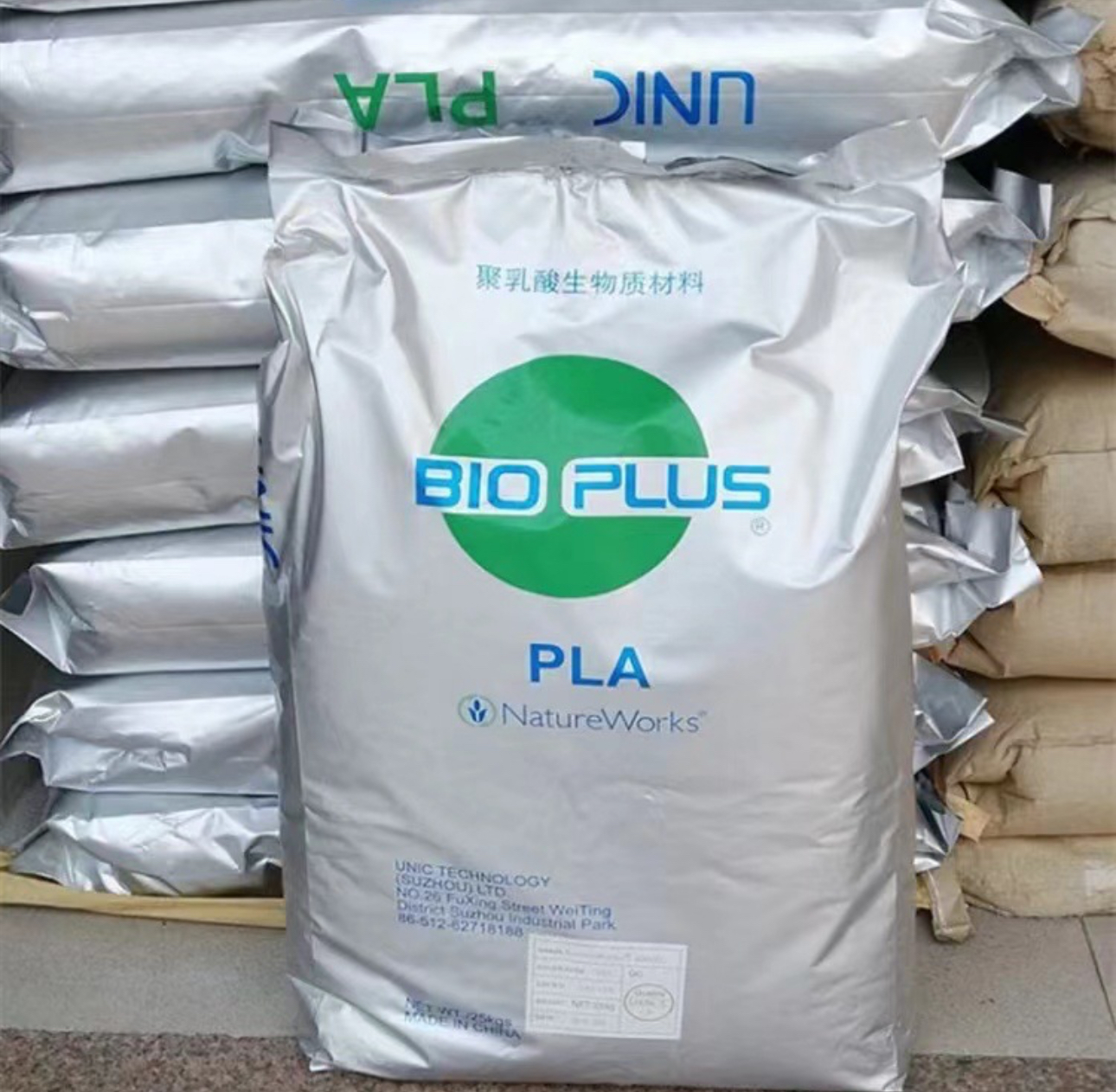

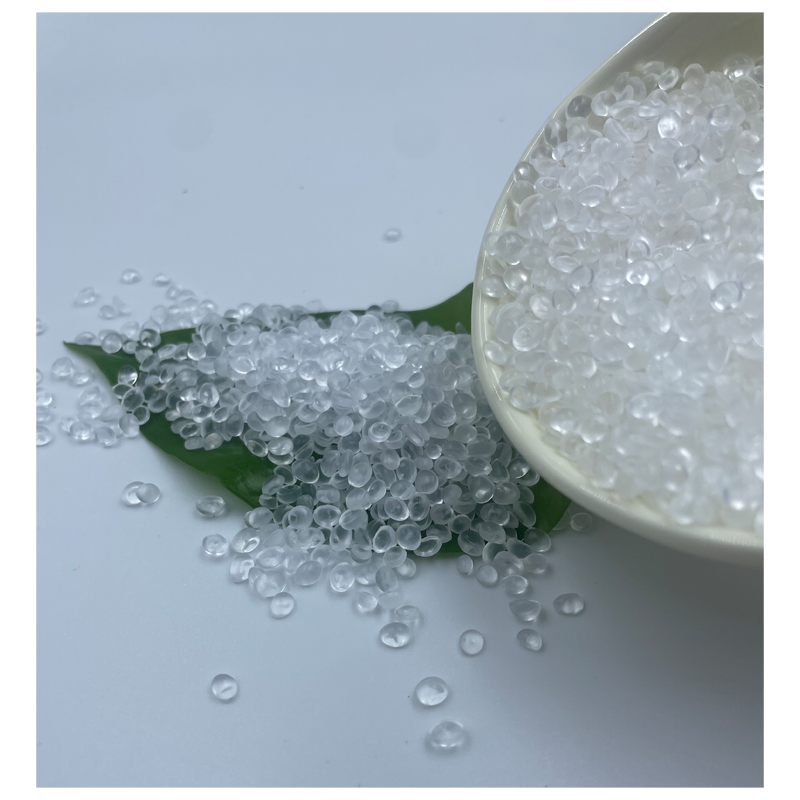

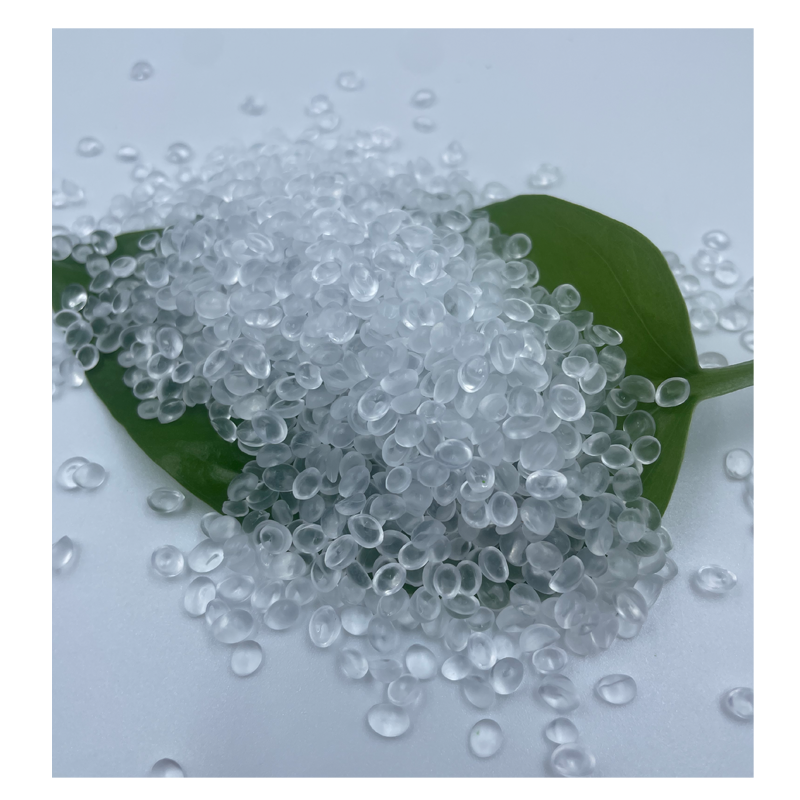

PLA Raw Material Biodegradable PLA 3D Printing Pellets PLA for Filament Resin Granules Low Price CAS 26100-51-6

PLA Raw Material Biodegradable PLA 3D Printing Pellets PLA for Filament Resin Granules Low Price CAS 26100-51-6

Packaging field** (accounting for about 40%)

- **Food packaging**: transparent beverage cups, cling film, degradable tableware (suitable for hot drinks after heat-resistant modification).

- **Daily chemical packaging**: cosmetic bottles, label films (printability modification required).

#### 2. **Medical field** (high added value)

- **Absorbable medical devices**: surgical sutures, bone screws, stents (L-PLA-based, degradation cycle matches tissue healing).

- **Drug sustained release system**: DL-PLA microspheres encapsulate drugs to control the release rate.

#### 3. **Textiles and non-woven fabrics**

- **Medical protective products**: degradable masks, surgical gowns (made by meltblown process).

- **Clothing fabrics**: blended with cotton to improve breathability.

#### 4. **3D printing** (rapid growth)

- **FDM filament**: environmentally friendly models, educational supplies (need to optimize interlayer adhesion).

- **Supporting materials**: water-soluble PLA copolymers (such as PVA/PLA composites).

#### 5. **Other fields**

- **Agriculture**: degradable mulch (to avoid soil pollution).

- **Automotive interior**: modified PLA for door panels and dashboards (need to be heat-resistant and UV-resistant).

---

### **Fourth, limitations and solutions of PLA**

- **Disadvantages**: brittleness, poor heat resistance, degradation requires industrial composting conditions (slow degradation at room temperature).

- **Improvement direction**:

- Chemical modification (such as copolymerization with PCL to increase toughness).

- Nanocomposite materials (adding montmorillonite to improve heat resistance).